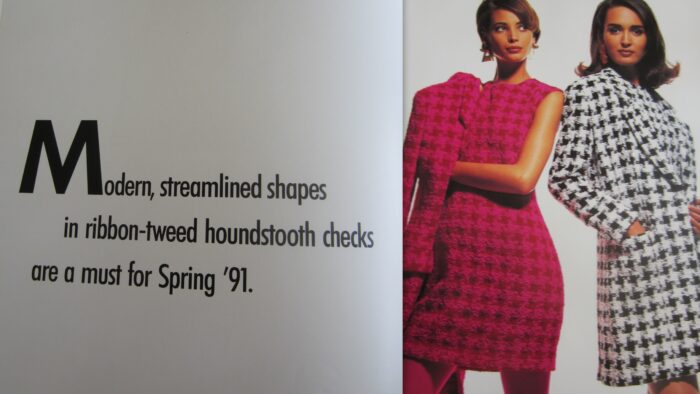

………………………….Tissage de Chaumes, the fabulous French fabric manufacturer that I worked with, developed these Ribbon Tweeds in a Hounds Tooth Check pattern. They were an incredible company. They had been in existence for over 100 years. The mill was a three story, wooden structure, and they still had many hand looms upon which they did production. They had rows and rows and rows of these high wooden structures that were divided into cubicles filled with different types of yarns in every color imaginable. If they didn’t have the right color they would dye it in another building. Unfortunately they closed many many years ago. The only company I know of that still can manufacture this way is in Scotland. They too made many of the Chanel tweeds…….The Hot Pink with Red, and the Black and Ivory colors repeat, now in these wonderful patterns. A simple fitted dress with its’ matching shaped coat was the perfect answer to special occasion dressing when the occasions weren’t too too dressy. When I was young everyone dressed for Easter Sunday……..these would have been perfect.

“A NEW VERSION OF THE RIBBON TWEED”

This Post Has 6 Comments

Comments are closed.

Did you learn about fabrics and where these specialized tweeds are made at Parsons? If somebody goes to a fashion Institute now, do they learn things like this or is it more centered on mass production? I have learned so much just in the last year from your blog.

Dear Andrea, Parsons was a great school, but they only taught the fundamentals of fabric, meaning what each fabric was capable of doing, how they would draping and tailor, and how they should be used, but it was very basic. I learned about fabrics from working with them. Every year there were huge fabric fairs in Germany, Italy and France, and I got to know all of the different mills at these shows. I also went to many of the mills in these countries and worked directly with them seeing what fabrics, and weaves they were working on and their complete lines of fabrics. I learned as I went along. Some designers never go to a mill, and some send assistants to the fabric shows to do the work, but they were in a word LAZY. The more hands on you are and the more you see the more you learn. I always LOVED fabrics so I looked forward to these trips even if they were exhausting.

Awesome!!! I would have to have BOTH jackets and

BOTH colors in the dress. Perfection. so, this company would ship the fabric to China, to make the dresses or send it directly to Anne K.? What did the fabric cost per yard, or bolt? How many dresses did they have to make yardage for? Obviously, they were set up to make as much as any designer would need. You were

so blessed to work with these connoisseurs !

NO, NO, NO…all Anne Klein Couture was made in the USA or Italy. Only Anne Klein 11 was made in China. These clothes were made in the us. They produced exactly the amount we ordered. The fabrics were so expensive there were no minimums.

So you had to absorb whatever they produced even if there was a surplus left over.

No, they made the yardage we ordered, not more.